Cutting-edge Test Facilities Available forResearch, Testing, or Purchase

Cutting-edge Test Facilities Available forResearch, Testing, or Purchase

Wide Range of Environmental Calorimeters

Physical Size and Capacity Ranges

- Chamber sizes up to 17m x 24m x 7m

- Capacity measurement capabilities from 100W to 400kW

Temperature Range: -40°C to 70°C or higher

- Up to 160°C for compressor enclosure

- Full range of humidity control

- ASHRAE Standard 41.2 wind tunnels to accommodate heat exchangers

- Air flow rates of 0 – 100L/s (0 – 200cfm) for small heat exchangers up to 0 - 40,000L/s (0 - 80,000cfm) or higher for industrial systems

- Variable

speed coolant pumps / bypass - PID controlled coolant immersion heaters for simulated battery loads

Unique 3 Independent Energy Balances Provide Quality Results

Measures system capacity in 3 different ways, independently

- Refrigerant-side measurement

- Air-side measurement

- Chamber-side measurement

Typically, all 3 measurements match within 3 - 5%

System Data Logging and Control

- Refrigerant cycles are displayed in real time

- PLC controls all hardware to maintain required operating parameters

Component Test Facilities

Standalone test facilities for component level testing to applicable standards.

- Wind tunnels for evaporators, condensers, coolers

- Refrigerant conditioning rigs for IHXs, valves, and other components

- Coolant conditioning rigs for chillers

- Calorimeters for compressors

The capabilities of our test facilities include performance testing and durability testing.

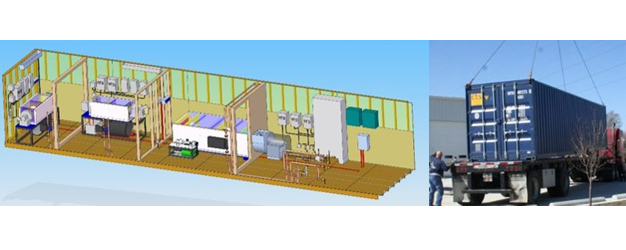

Transportable Laboratories

All capabilities in typical automotive chambers are also available for a standalone lab built into a shipping container.

Indoor Chambers

- ASHRAE Standard 41.2 wind tunnels to accommodate evaporators

- Typical airflow rates of 0 - 150L/s (0 - 9000L/min)

- Full range of humidity

Outdoor Chambers

- ASHRAE Standard 41.2 wind tunnels to accommodate condensers

- Typical airflow rates of 0 - 1000L/s (0 - 60 m3/min)

Chiller / Simulated Battery Cooling Loops

- Variable speed coolant pumps / bypass

- PID controlled coolant immersion heaters for simulated battery loads

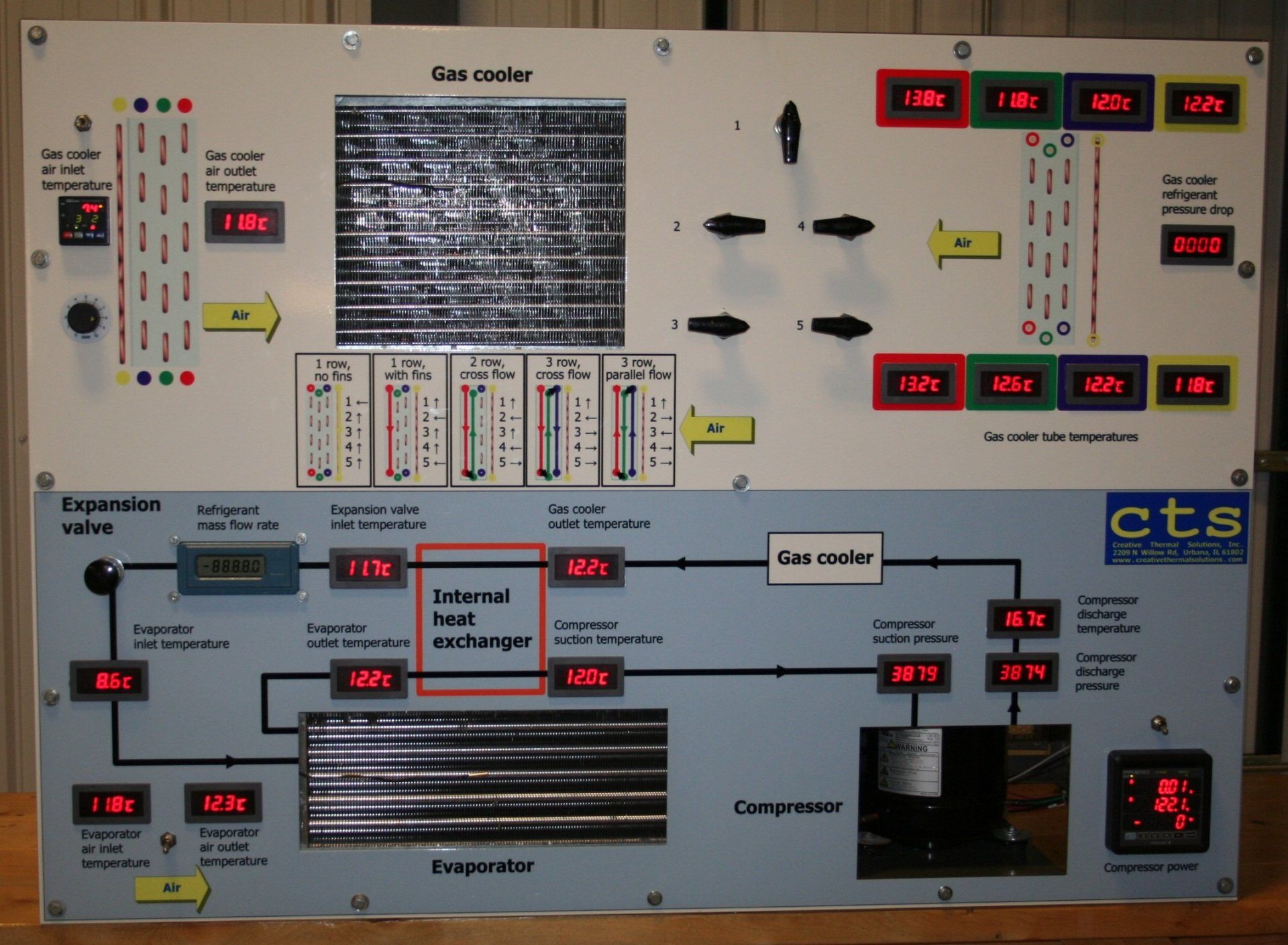

Custom Training Units and Demonstrators

Our training units are designed to demonstrate important considerations in A/C and refrigeration systems and component level design.

- Alternate refrigerants and cycles

- Component designs

- Condenser / gas cooler, evaporator, IHX, compressors

- Charge determination

- Capillary tube sizing

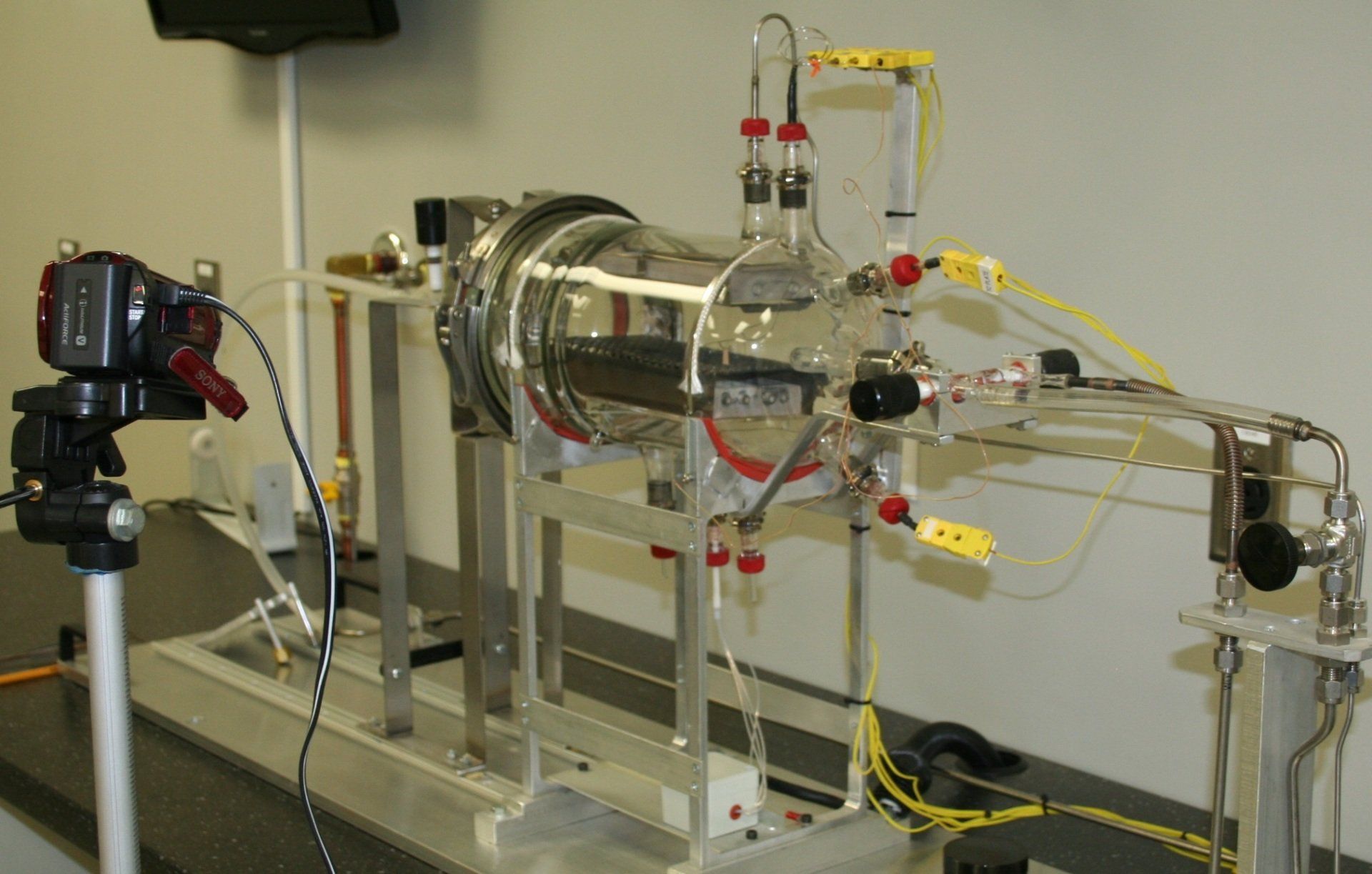

Transparent Brazing Furnace

Features

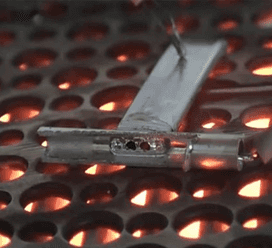

- Real time visualization of Controlled Atmosphere Brazing (CAB) of aluminum alloys

- Furnace dimensions: 140 mm in diameter, 250 mm in length

- Gas inlet and outlet for atmosphere control

- Optional top heater installation

- Multiple thermocouples (K type) for temperature measurement

- Pressure sensor for monitoring chamber pressure

- Multiple chamber ports for additional instrumentation and vacuum purge (optional)

- Tabletop aluminum frame for supporting

furnace chamber

Control and data collection unit

- Gas flow control panel

- Dew point sensor and transmitter

- Electrical control panel

- Heater controller

- Data acquisition system

- Movable cart for instruments and control panels