Develop State-of-the-Art Products

Experimental Research, Analysis and Consulting, Design, Simulation, and Prototyping Capabilities

Working confidentially with you on many levels to enhance your products

- Increased system performance (heating/cooling capacity and efficiency)

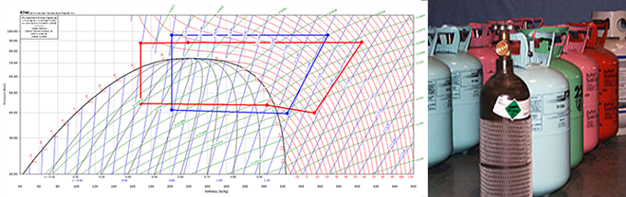

- Implementation of alternative refrigerants

- Lower GWP

- Enhanced performance

- Reduced flammability or toxicity

- Integration of novel technologies

- Decreased weight and/or volume of system

- Overall refrigerant charge reduction

- Cost reduction

Experimental Research

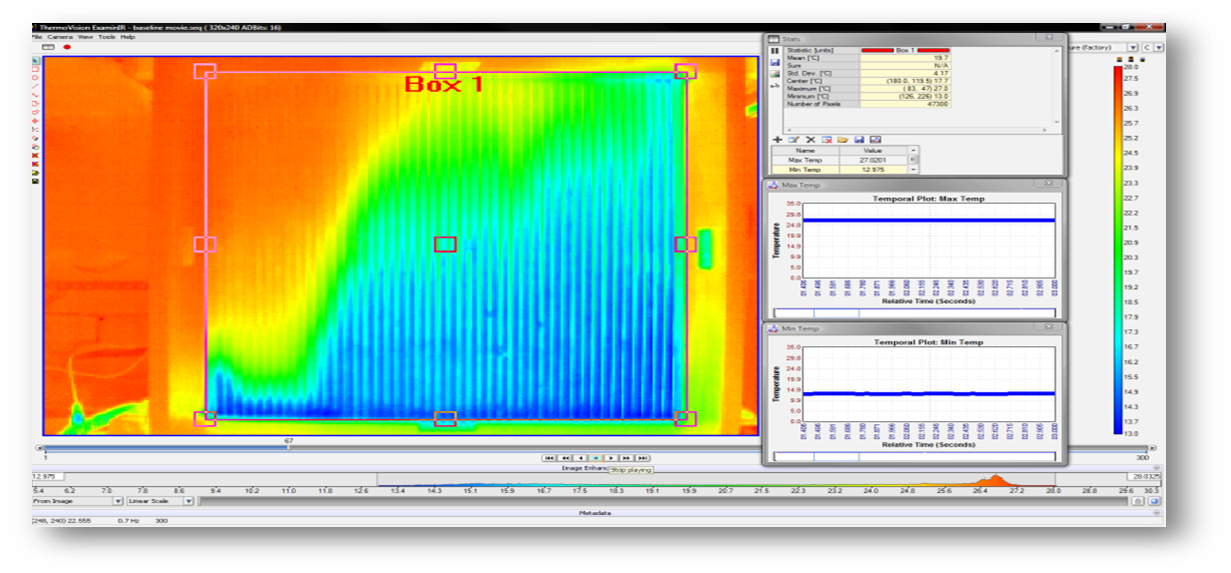

Cutting-edge facilities to explore full systems, system components, and perform fundamental research

- Study of alternative natural and man-made refrigerants

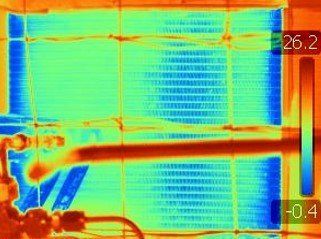

- Observation of distribution in heat exchangers and their headers

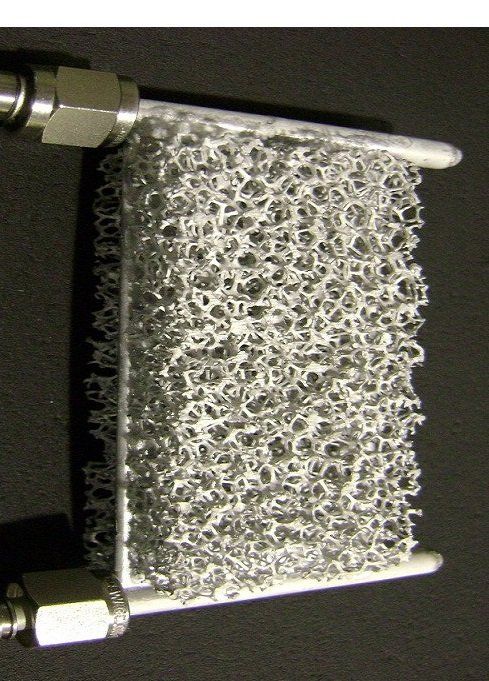

- Study of pressure drop, heat transfer, fluid mixture properties, two-phase fluid flows including those related to sub-millimeter length scales

- Analysis of efficiency and design of various flow separators

- Destructive and nondestructive durability testing

- Analysis of acoustic profiles from compressors and issues in heat exchangers and expansion devices including implementation of noise mitigation solutions

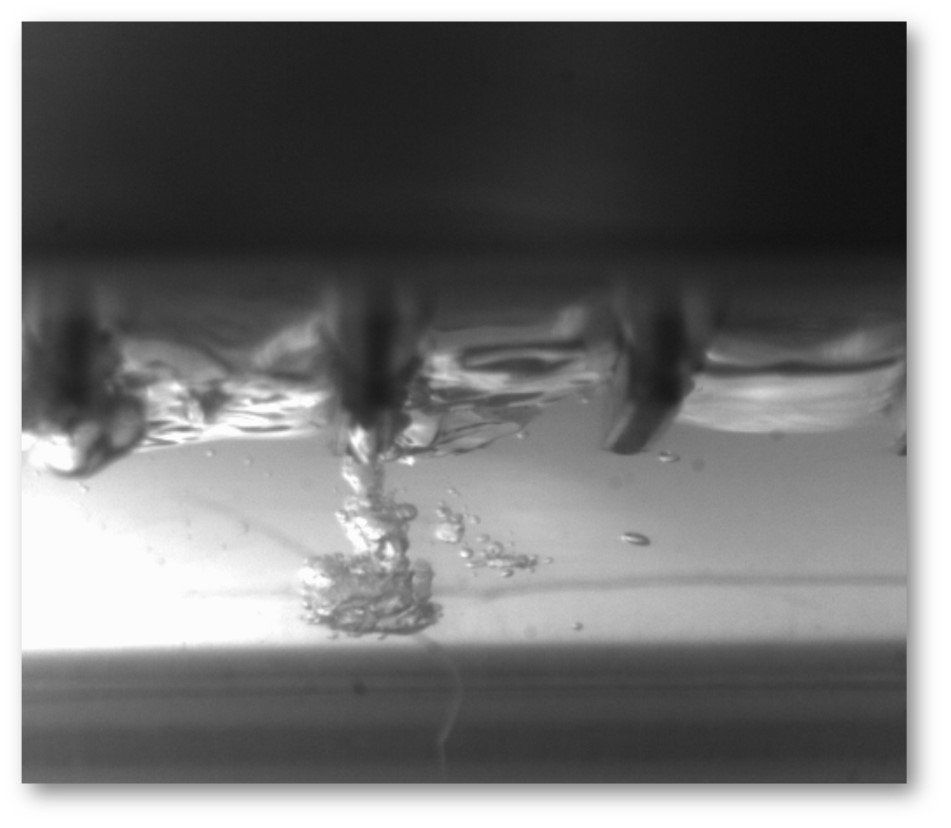

- Visualization of flow through novel expansion devices

- Visualization of compressor discharge

- Precise measurement of leakage rates of various refrigerants

Analysis and Consulting

- Accurate and repeatable experimental and simulation data

- Analysis and understanding behind the data

- Observations and results meaningful to your application

- Consulting services to help clients better understand their own experimental or performance data to provide valuable results and optimized designs

Product Design

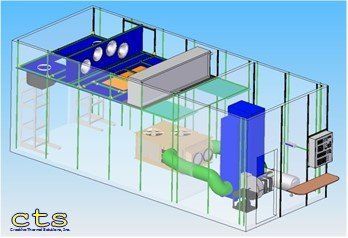

- Expertise in novel product design

- Services for customers looking for innovative new products

- Consulting yielding improvements to existing products

- Design activities accompanied by prototyping services

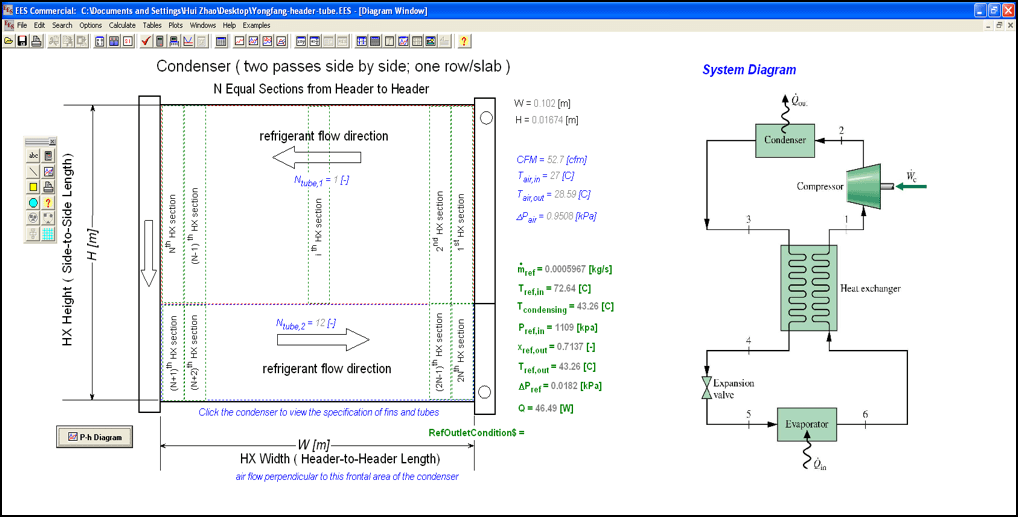

Simulation

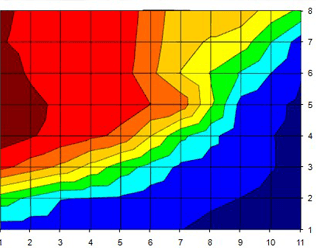

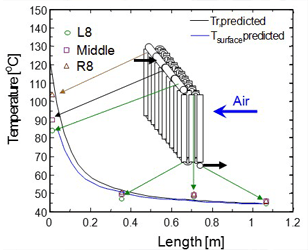

- Modular, In-house CTS written simulation models used to predict system and component performances

- Computation models are used in design as well as analysis and optimization of the elements under examination

- Predict system and component performances

- Models are validated and refined over a wide range of operating conditions

- Vast experimental database to validate simulation models

- Typical 5% accuracy match of dynamic and steady-state system response (ie cooling capacity and energy efficiency-COP) to experimental data

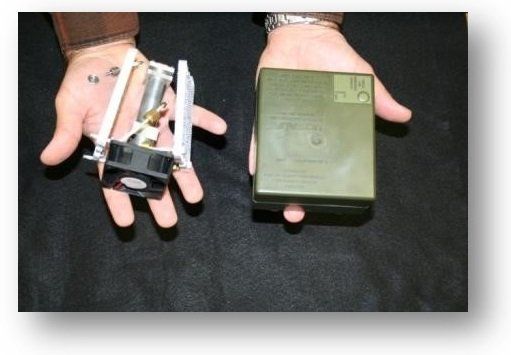

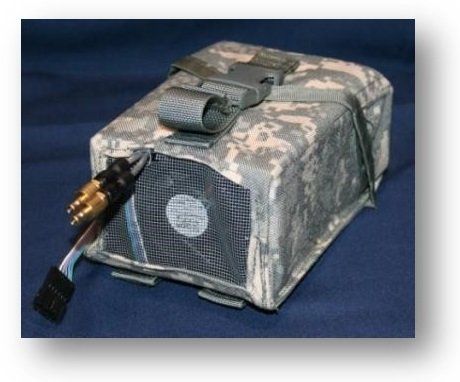

Prototyping

Custom fabricated solutions for any stage in the design, development, or product engineering processes

- Special units for in-house testing

- Custom components

- Turn-key, one-off products

- Demonstration models