Supporting copy for the Request Service

call out button.

Testing Facilities and Products

Cutting-edge Test Facilities Available forResearch, Testing, or Purchase

Cutting-edge Test Facilities Available forResearch, Testing, or Purchase

Wide Range of Environmental Calorimeters

Physical Size and Capacity Ranges

- Chamber sizes up to 17m x 24m x 7m

- Capacity measurement capabilities from 100W to 400kW

Temperature Range: -40°C to 70°C or higher

- Up to 160°C for compressor enclosure

- Full range of humidity control

- ASHRAE Standard 41.2 wind tunnels to accommodate heat exchangers

- Air flow rates of 0 – 100L/s (0 – 200cfm) for small heat exchangers up to 0 - 40,000L/s (0 - 80,000cfm) or higher for industrial systems

- Variable

speed coolant pumps / bypass - PID controlled coolant immersion heaters for simulated battery loads

Unique 3 Independent Energy Balances Provide Quality Results

Measures system capacity in 3 different ways, independently

- Refrigerant-side measurement

- Air-side measurement

- Chamber-side measurement

Typically, all 3 measurements match within 3 - 5%

System Data Logging and Control

- Refrigerant cycles are displayed in real time

- PLC controls all hardware to maintain required operating parameters

Component Test Facilities

Standalone test facilities for component level testing to applicable standards.

- Wind tunnels for evaporators, condensers, coolers

- Refrigerant conditioning rigs for IHXs, valves, and other components

- Coolant conditioning rigs for chillers

- Calorimeters for compressors

The capabilities of our test facilities include performance testing and durability testing.

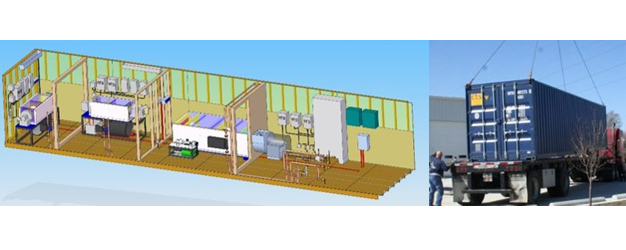

Transportable Laboratories

All capabilities in typical automotive chambers are also available for a standalone lab built into a shipping container.

Indoor Chambers

- ASHRAE Standard 41.2 wind tunnels to accommodate evaporators

- Typical airflow rates of 0 - 150L/s (0 - 9000L/min)

- Full range of humidity

Outdoor Chambers

- ASHRAE Standard 41.2 wind tunnels to accommodate condensers

- Typical airflow rates of 0 - 1000L/s (0 - 60 m3/min)

Chiller / Simulated Battery Cooling Loops

- Variable speed coolant pumps / bypass

- PID controlled coolant immersion heaters for simulated battery loads

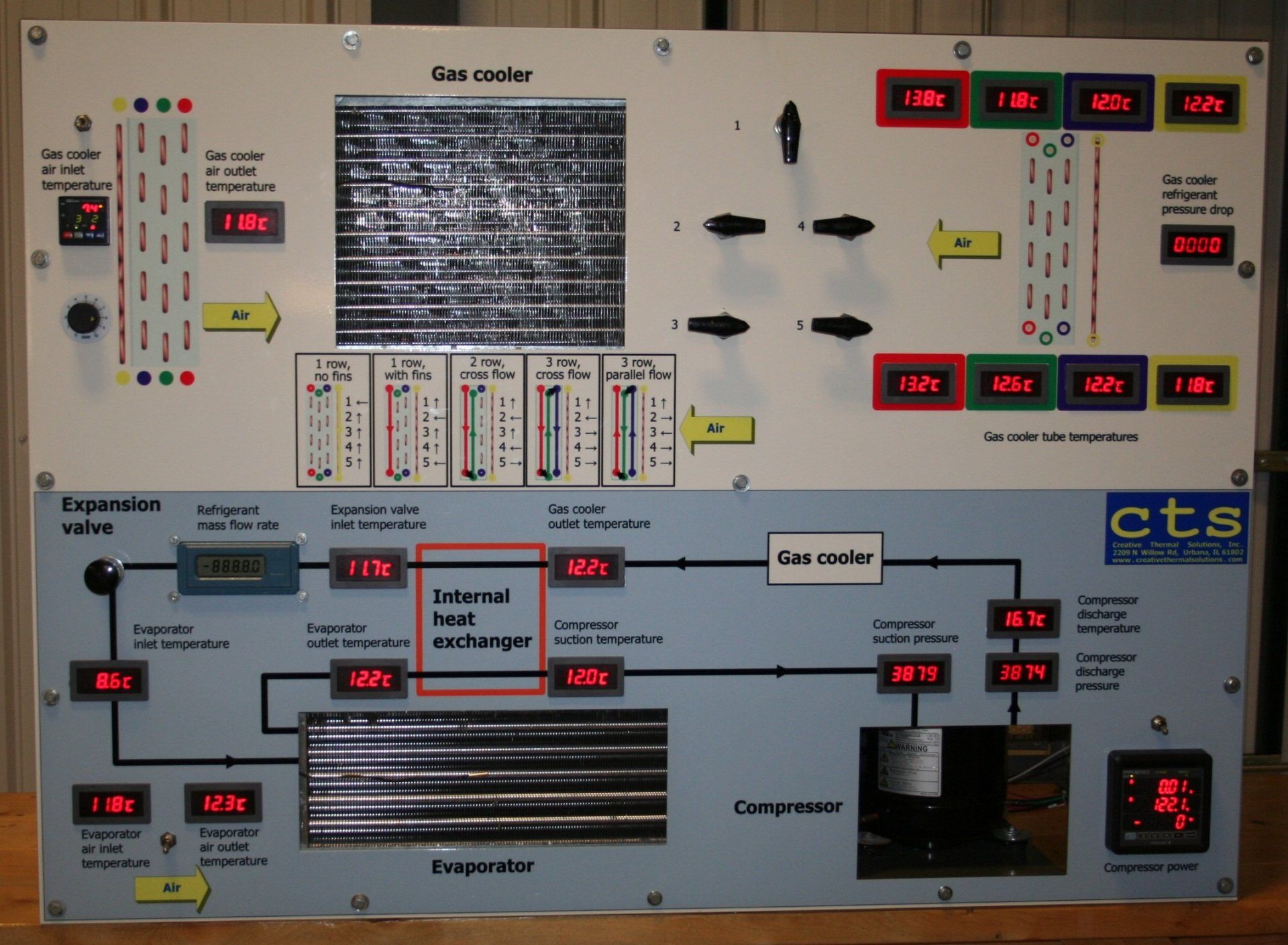

Custom Training Units and Demonstrators

Our training units are designed to demonstrate important considerations in A/C and refrigeration systems and component level design.

- Alternate refrigerants and cycles

- Component designs

- Condenser / gas cooler, evaporator, IHX, compressors

- Charge determination

- Capillary tube sizing

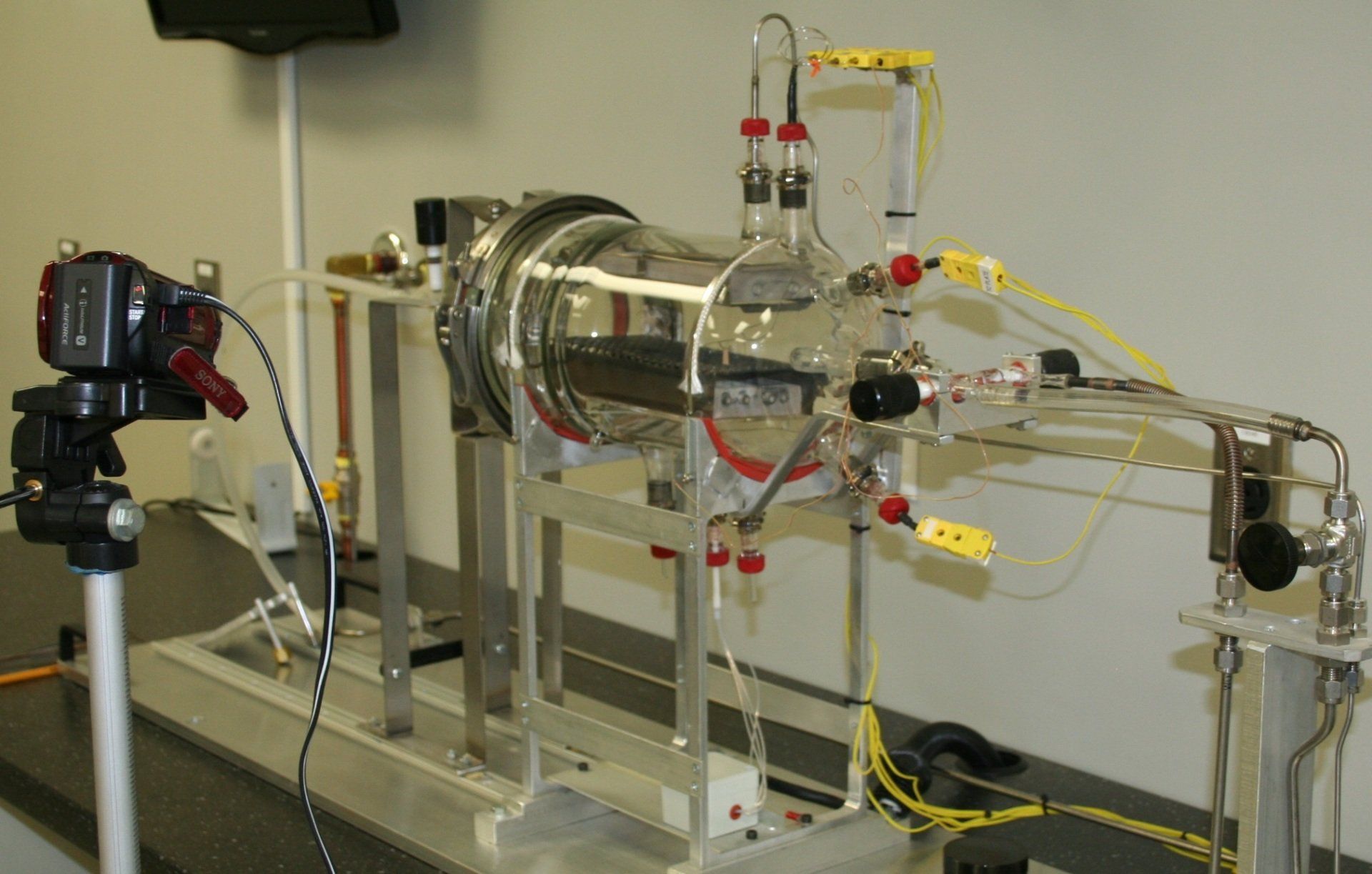

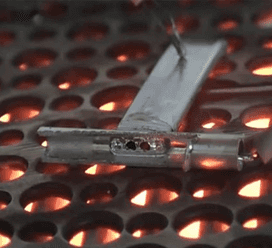

Transparent Brazing Furnace

Features

- Real time visualization of Controlled Atmosphere Brazing (CAB) of aluminum alloys

- Furnace dimensions: 140 mm in diameter, 250 mm in length

- Gas inlet and outlet for atmosphere control

- Optional top heater installation

- Multiple thermocouples (K type) for temperature measurement

- Pressure sensor for monitoring chamber pressure

- Multiple chamber ports for additional instrumentation and vacuum purge (optional)

- Tabletop aluminum frame for supporting

furnace chamber

Control and data collection unit

- Gas flow control panel

- Dew point sensor and transmitter

- Electrical control panel

- Heater controller

- Data acquisition system

- Movable cart for instruments and control panels

About Our Business

CTS provides professional, confidential, consulting services by working with clients to serve their needs, research potential solutions, and successfully complete objectives. Whenever possible CTS tries to go beyond direct requests and provide additional insights that may be helpful for further improvements of the concept or the product.

Contact Our Team

Creative Thermal Solutions Inc

2209 North Willow Road

Urbana, IL 61802

217-344-7663

Privacy Policy

| Do Not Share My Information

| Conditions of Use

| Notice and Take Down Policy

| Website Accessibility Policy

© 2024

The content on this website is owned by us and our licensors. Do not copy any content (including images) without our consent.